Peronalized Four Finger Rings

THE WHY OF IT:

I like making things for people. So a creating series of Brass knuckles for a special sub-set of badasses in my life began.

I’ve been saving up - slowly - for a motorcycle. The people in my life who I know have already or will be so mega important that my motorcycle does not become a rotting cesspool of rusted junk I so appreciate. I had one back in 2010 and it slowly turned into aforementioned garbage because I did not know how to plan, and then care for the bike once I got it.

So, I am pre-thanking those in my life who I know will help me ride, ride safely, but also keep me going. Just having them in my life means I might be able to swing it this time, and to me, a motorcycle is freedom and after this 2020 year, I really really need some freedom. What better way to say thanks, than to make them something just for them, and a personalized set of brass knuckles seemed interesting enough for me to make, both on design and fabrication fronts.

THE DESIGN OF THEM:

-Design per individual

Fit test

chamfers/lolipop recesses in rings

length and width of palm section

curvature of finger postions

Hitter features

It is essential in the deign stages to consider what is and is not machinable (subtractive processes generally)

DFM:

Design for Manufacturing (pertinent to our design):

Add Radii to Internal Vertical Edges:

Ideally, the corner radius should be slightly larger than the radius of the tool that will be used to machine the cavity. This reduces the loads on the tool and will further reduce your manufacturing costs.

The deeper the cavity to be machined, the larger the radii must be (it is typically half the diameter of the cutting tool or larger).

For example, if your design has a 1” deep cavity, add a 1/8” (or larger) radius at the corners. This will allow a 1/4” diameter tool with an 1/8” radius to cut them at a faster speed.

If you can accept a larger radius at the corners, the machining time will be faster, as the larger a tool’s

diameter, the more efficient material can be removed and the deeper the cavity can be.

Designing parts which have sharp right angled internal pockets can cause several semi serious issues.

These can be contained a bit by CAM and toolpath configuration, but best is to design without that requirement.

When a geometry is selected which is right angled and internal, the toolpath is configured by selecting that geometry, and the tool will attempt to go to that internal right angled edge.

This can cause damage to the tool if cutting aggressively at worst.

At best, the tool will deflect, unless constrained inside the toolpath in CAM, and will cause incident marks on your part.

The larger the radii the better.

The red portion of the image on the far right shows a radial engagement of far more than the cutter can efficiently and/or successfully achieve.

Dogbone/ recesses:

Remove corners completely, in a manner of speaking.

The deeper your pocket (or the thicker your material, if cutting the profile of the part), and the tighter your corner radius has to be, the harder it will be to machine.

If internal edges with sharp corners are required (for example, when a part with rectangular shape needs to fit in the cavity but the corner is irrelevant), instead of reducing the radius of the internal edges, use a shape like the below examples:

When a part with rectangular shape needs to fit in a cavity, add undercuts to the corners of the cavity.

Limit the Depth of Small Cavities and Consider X + Y area:

Limit the depth of cavities to 4 times their length: Special tooling may need to be used, deflection carefully controlled for and many many other considerations have to be made.

So, in short form - A cutting tool must ramp or lead into a workpiece.

It needs the appropriate room to do so.

The stickout and flute length of the tool must be able to go to the total depth of the feature designed. The longer the stickout of a tool, and the smaller the diameter of that tool, the more deflection will occur to the tool, potentially breaking the tool at the worst or costing machining time and will show markings of the deflection on the component.

NOTE: affecting the finish phrases is also affecting the tolerance. Deflection is a finish issue and the more deflection the less accurate a component is.

Tool Spacing Considerations/Text and letters:

Remember to take into account the tools that will be used to make your part. For example, if you must create an undercut, you have to leave room for the tool to be fed in. As the tool is round, the added clearance required to allow the tool to be lowered into position is doubled for every increase in radial depth of the undercut. This is because the full diameter of the cutter must be accounted for, while the depth is determined by the tool’s radius.

Above you can see the effect on necessary clearance of having to use the larger red cutter to create the larger undercut shown in the lower image.

Avoid sharp letters and deep features. Ensure the cutting tool diameter can fit in between all features (double checking the letters can accommodate and that the spacing between them can accommodate).

It is recommended to use font family like BOLD Sans-Serif e.g. Arial, Verdana, or Helvetica as they have fewer sharp features.

MASTER BLANK DESIGN

——> the first set I designed was for the lurkshop set. I focused most of the design constraints to meet the large-dude-hands for whom these were intended. The logic behind this was that smallerization in design is always easier than biggerizing.

So the work of creating a Template for all other designs started with rough vector sketches laser cut to test spacing, arc of hand placement, length for the palm to grip etc.

Each of these designs were just not good.

Each showed elements of what I was after but did not really have what I was looking for in terms of aesthetics/ergonomics/machineability.

Ultimately I cam to the final design after doing tests on friends with big hands, measuring diameters, about spacing etc.(I have very small hands so I was not a candidate for testing)

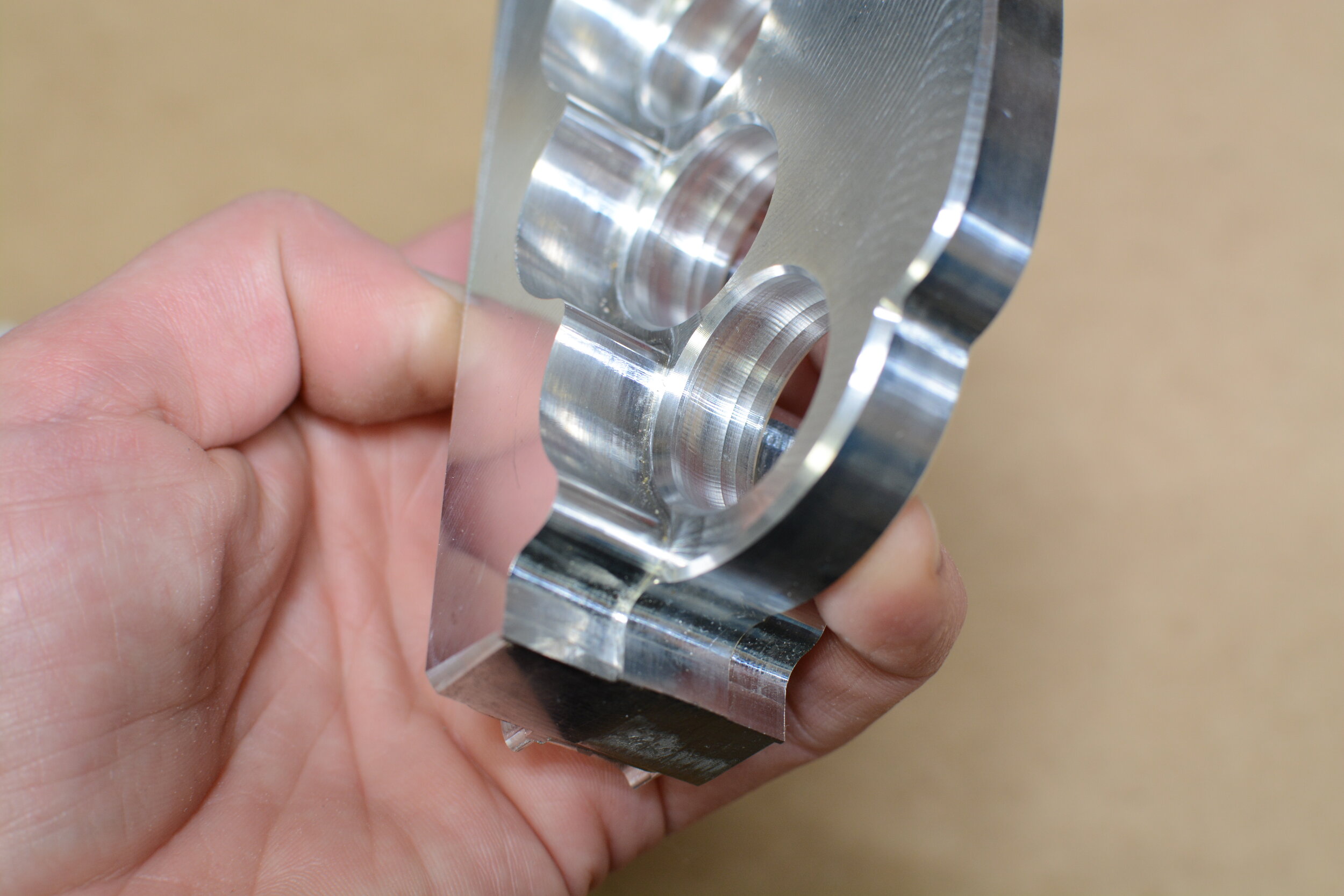

Only for my set of knuckles did I modify the diameters of finger holes.

Feel free to download this design and inspect the features.

LINK TO FINAL BLANK STEP FILE HERE.

THE MACHINING OF THEM:

Of a 6 sided bit of stock we will be machining 5 of them individually. So let’s go through the options of how/what/order of operations etc. The puzzle of a setup is one of the most fun things about machining.

Tricky Geometry

several machining errors. impatient with finishing the logo as was test.

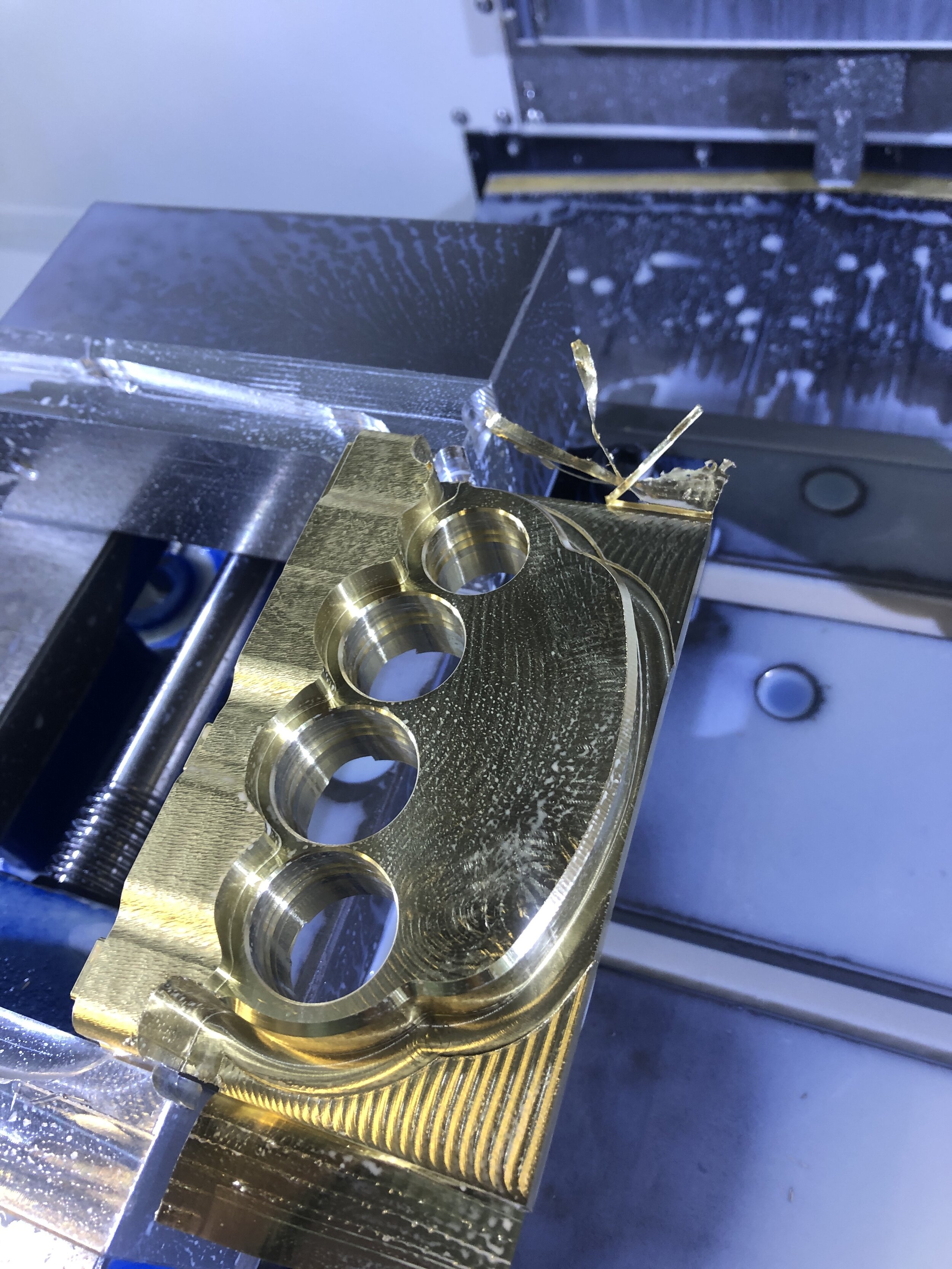

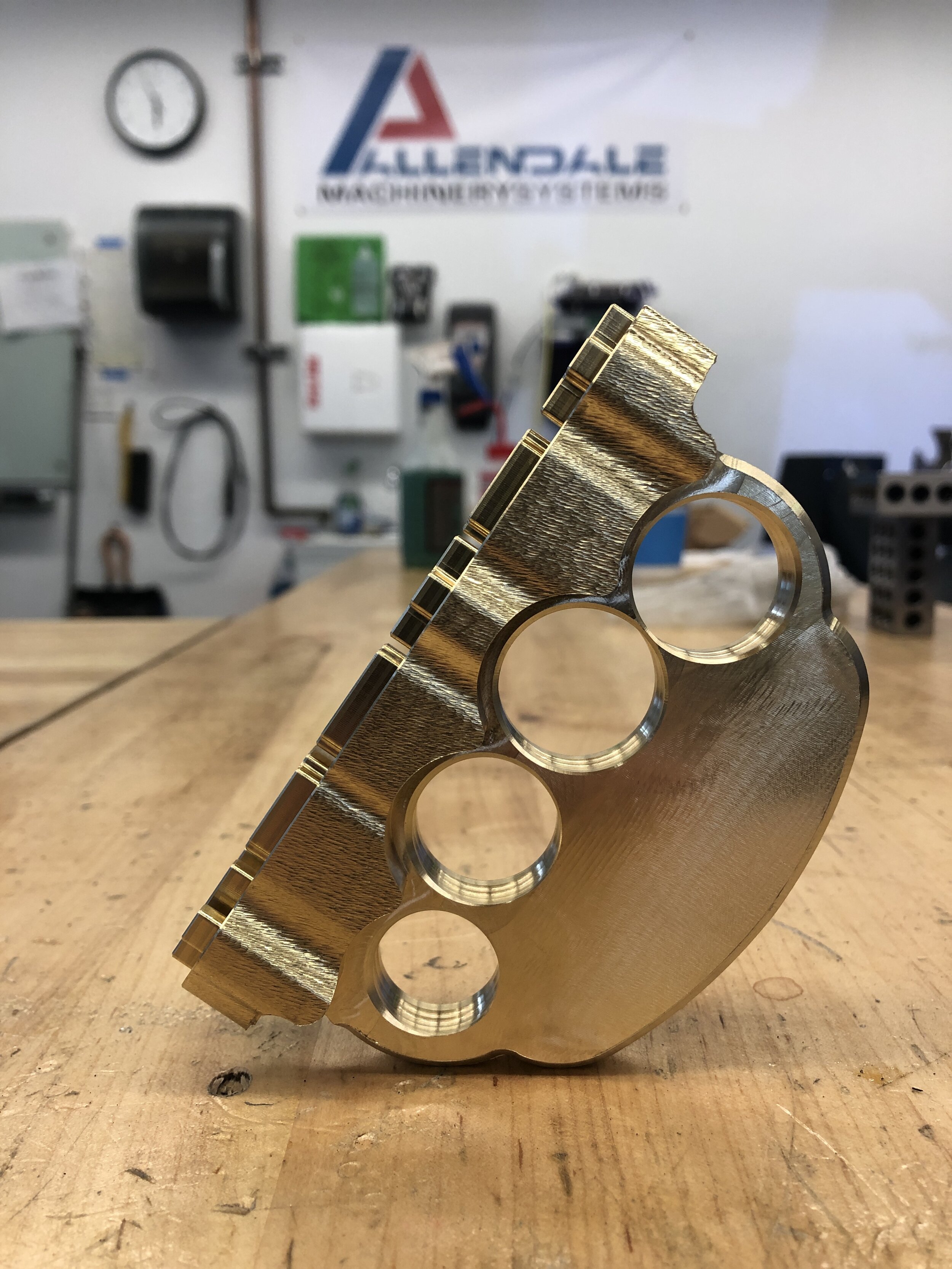

KNUCKLES IN PROCESS

LURKSHOP

dimensioning stock

1/8'“ roughing

1/16” roughing